At a time when the graphic arts industry is facing a chronic labor shortage, an increasing number of small print jobs, and ever-shorter delivery deadlines, those who know how to combine technology, speed, and organization have the best chance of survival and growth.

The printing house Galesnik from Split is a perfect example of this. Their success is not the result of chance, but of a clearly defined strategy, smart investments, and trust in a single partner. Every phase of their development has been linked to Konica Minolta, from which they acquire all equipment and software.

From the very beginning, Galesnik focused exclusively on digital printing with fast turnaround times. Their business model is built on high efficiency, automation, and continuous investment in technology.

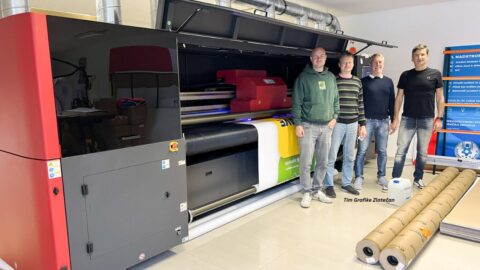

We first visited them in 2023 when they invested in the AccurioLabel 190, taking their first steps into the label printing market. Today, two years later, we are once again witnessing a major milestone. The AccurioPress C12000e has arrived in their production, featuring the most advanced configuration currently available in the wider region.

But the story of Galesnik goes far beyond the technology itself. It is a complete digital transformation of their business—from machines and software to a new philosophy of production and services.

Fast Printing as Identity

“From the beginning, I knew that besides quality, our advantage would be speed,” says Mr. Dino Markic, owner of Galesnik. A delivery time of 24 to 48 hours has become their standard, recognized by the market. However, this requires specific organization and technology. “We often work in three shifts, especially before the tourist season. And since the labor shortage is a constant issue, we must move toward automation and stable capacity. The market demands more, faster, better—and we respond with Konica Minolta technology,” adds Mr. Markic.

A major leap forward was made two years ago with the investment in the AccurioLabel 190—a machine that, as the owner said at the time, was a visionary investment.

AccurioPress C12000e – When Volumes Become Serious

Galesnik’s production continues to grow, and their newest investment, the AccurioPress C12000e, arrived this spring. It is a nine-meter-long line, unique in the region, equipped with complete inline finishing and a dual-drawer system for handling various materials. “With this machine, we accelerated the process five to ten times and replaced at least two operators,” explains Mr. Markic.

He adds that the numbers speak for themselves: “We completed our planned annual volume in just two months, almost one million prints,” he says.

Behind the hardware power stands Konica Minolta AccurioFlux, an advanced workflow system that has become the central tool in the printing house. “Flux is like an additional employee and just as important as the printer. All machines are connected to it, and I have a perfect overview of all jobs,” says Mr. Markic.