Grafoprojekt (Croatia) is a company that consistently follows and implements technological innovations in its production. The recent investments in the Ricoh Pro C7500 and the Duplo DC-618 finishing system were the occasion for a conversation with the company’s leaders. Mr. Goran Bozanic, Mrs. Masa Bozanic, and Mr. Petar Bozanic shared how new technologies enhance their business and strengthen Grafoprojekt’s position in the market.

When it comes to investing in new technologies, Grafoprojekt takes a very responsible and strategic approach.

“Experience has taught us to approach new investments only after a detailed analysis that must answer what the new technology brings to our customers and how well it integrates with existing systems and capacities. A poor investment today is a mistake that’s costly to correct — but not investing at all can be just as big a mistake,” says Mr. Goran Bozanic.

A Balanced Printing and Finishing Process

Regarding their latest investment in the Ricoh Pro C7500, they say it was a logical step forward since they previously used the Ricoh Pro C7100.

“The new printer has not only increased our speed but also brought the ability to print metallic colors and better control over consistent print quality. We also value its improved performance on textured papers and the ability to print on heavier cardstock. I believe the capability to print on sheets up to 96 cm long will also prove useful,” emphasizes Mr. Petar Bozanic.

Since the print speed of the Ricoh Pro C7500 requires balanced finishing capacities, they identified a bottleneck in handling small print runs and invested in the Duplo DC-618 finishing system, which they describe as an optimal solution thanks to its versatility and quick setup.

Eurocop – Partner, Advisor, and Support

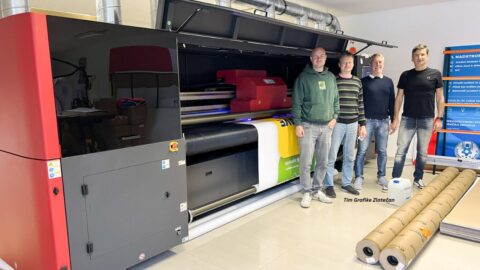

They decided to implement the new equipment in two phases. The first phase, they say, took only a few days, during which they utilized 95% of the machines’ capabilities. In cooperation with Eurocop, the supplier and installer of the systems, they planned the second phase for when they would gain more user experience and encounter challenges that could be solved more efficiently with Eurocop’s assistance.

“As I mentioned, we don’t make investment decisions lightly. Each one goes through detailed analysis and verification. In that process, Eurocop is an extremely valuable partner — providing access not only to top-quality equipment but also to continuous support throughout the decision-making process. We especially appreciate their patience, collaborative approach, and the opportunity to test equipment in real working conditions. That kind of partnership gave us extra confidence and strongly influenced our latest investment decision,” concludes Mr. Petar Bozanic.