As the boundaries between traditional and digital printing continue to blur, Belgrade-based Fine Art stands as an example of a print house that recognized the right moment and found the courage to change direction. Fine Art demonstrates how bold decisions and smart investments can lead to digital excellence. This is why it is increasingly the choice of those seeking top-tier quality and creative freedom in large-format applications.

How did the journey unfold from traditional offset printing to modern large-format digital production? What challenges did they face, and why was the partnership with IGEPA Polikarbonati crucial in that process? These questions were answered by Mr. Djordje Obradovic, owner of Fine Art.

What was the key moment when you decided to move from offset to digital printing? Why focus on large formats?

The key moment for Fine Art came when we recognized changes in the market and a growing need for faster, more flexible, and higher-quality printed solutions. We decided to move away from traditional offset printing toward digital printing because it allowed us to become more competitive, respond more quickly to customer demands, and offer a wide range of products in larger formats. The turning point came when we realized that digital printing brings greater efficiency, lower costs for short runs, and the possibility of personalization, everything that is essential for success today. All of the above processes are the main reasons behind the founding of Fine Art.

What were the biggest challenges along this transformation journey?

The challenges were both organizational and mental. Organizationally, we had to invest in new equipment, train employees to work with digital machines, and adapt our production processes. This required a significant logistical and financial transformation. We also had to redefine our internal routines and collaboration, as digital technologies brought greater flexibility but also demanded stricter quality control and higher technical requirements.

On the other hand, it was necessary to change the mindset within the team and among employees. There was a natural level of fear of the unknown, but we invested in training and employee support. We realized how important it was to motivate the team and provide them with security in the new system. This transformation process was challenging, but ultimately it led to increased efficiency, quality, and competitiveness of our company. Today, most employees confidently use the new machines and technologies, and the entire team has become a group of true experts in working with the latest equipment.

In which segment was your collaboration with IGEPA Polikarbonati most valuable at the time? What does this partnership look like in practice today?

Cooperation with IGEPA Polikarbonati proved to be extremely important, especially in the procurement of high-quality materials and equipment for large-format printing. From the very beginning, they provided support in selecting innovative materials that helped us raise product quality and meet the demands of an increasingly demanding market.

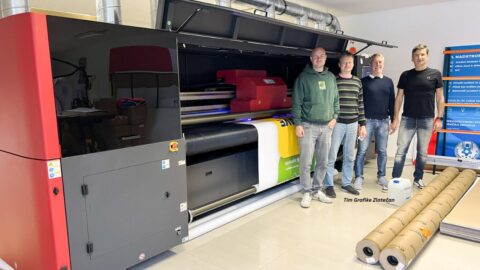

Today, our partnership with IGEPA Polikarbonati continues to grow stronger. This successful and solid cooperation is reflected in our latest projects as well. With their support, we acquired high-quality equipment, including a HandTop UV printer and a Jwei flatbed cutter, which enables broader application and greater production capabilities. This equipment provides us with technological advancement, greater flexibility, and improved efficiency. IGEPA Polikarbonati remains our reliable partner in supplying premium materials.