Very efficient and flexible Roland VersaUV LEC2-640S-F200 was installed at the end of last year in the Slovenian printing house Bucik Ltd. Although we have encountered different variations of UV technology on the market, from roll-to-roll printers, flatbed and hybrid UV printers, this is the first installation of this Roland model in our region.

This is a model whose entire work table, measuring 160x200cm, is movable and has a built-in belt. The length of the print is not limited because of the belt.

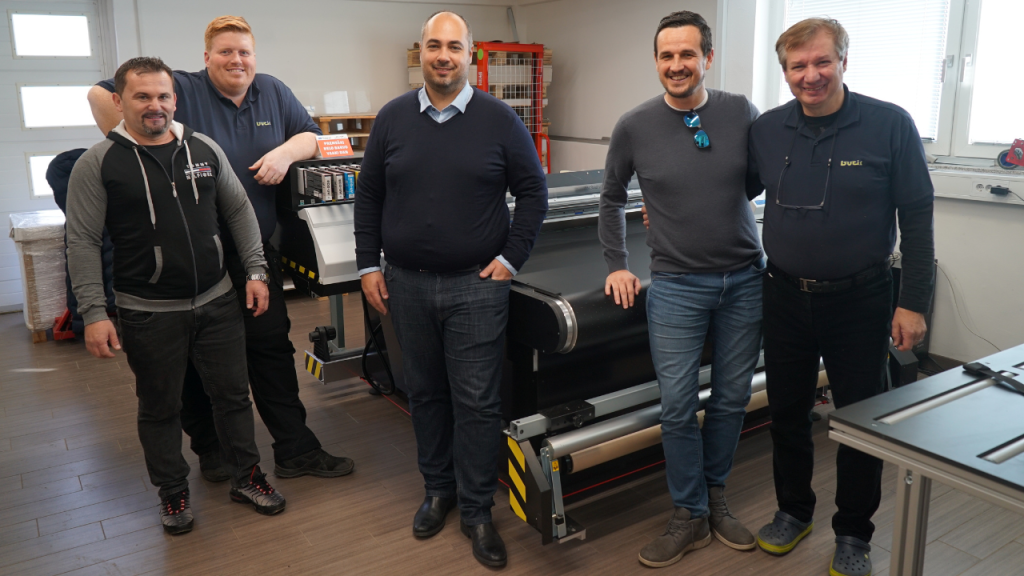

More about the printer told us Mr. Vjeko Krizanic, owner of the company Dipa, which delivered and installed the machine. The reasons for the investment were explained to us by Mr. Simon Bucik, director of the Bucik printing house.

Mr. Krizanic, what is it that sets this model apart from other UV printers on the market?

The basis of this UV printer is the Roland VersaUV LEC2-640 series. The series has been on the market for four years and belongs to the best-selling series of Roland printers.

In our market, we have sold more units, but roll-to-roll purposes. This is the first hybrid with a moving belt. It is unique in terms of the range of applications it is intended for and the range of media it can print on. It is used for printing on classic flexible materials for the graphic industry such as banners, art canvas, self-adhesive labels, wallpapers, fabrics. From rigid materials, it is used for printing acrylic, polymer, composite panels, glass, metal, wood and many others. In the promotional industry, printing on agendas, lighters, ballpoint pens, USB sticks, while in the case of special media, it is necessary to mention printing on designer cardboard for the production of luxury boxes or printing on metallic, gold, silver or transparent self-adhesive foil for the production of luxury labels.

The utility value of this printer is beyond the reach of the competition. The height of the work table is 23cm, which opens up the possibility of printing on objects of larger dimensions. Also, because of the white color and varnish, the printed products get a touch of luxury.

Mr. Bucik, you are the first in the region to have Roland’s hybrid flatbed. What was the reason for the investment?

We have had a Roland printer in our facility for 14 years. We use it to print labels that we later laminate and place as information signs in the interior and exterior.

During the last three years of Covid-19, the labeling segment has grown significantly, especially in healthcare institutions. By direct printing on plate materials, we significantly speed up the production process and eliminate the production of significant quantities of PVC labels and lamination from the cycle.

As I said, the ecological aspect is very important to us. With this technology we contribute to the preservation of our environment to a significant extent, but also meet the ecological requirements of our clients.

Due to the large working movable table, it is ideal for printing on sheet and flexible materials, and it does not take up a lot of space in the plant. Given the limited space we currently have, the Roland VersaUV LEC2-640S-F200 fit in perfectly.

Also, one of the reasons for the investment was the white color and the possibility of applying varnish. Namely, in addition to the marking program, white paint and varnish will enable entry into the segment of production of more luxurious labels and small series of packaging. The packaging or labels with which these products are marked require more luxurious materials, as well as more luxurious printing. The technologies used in the last decade no longer meet the needs of our users.