That there is enough space for business development in personalized textile production is evidenced by the young team from Croatian company Total sport.

The owner of Total sport, Mr. Vladimir Suvajac, is an economist by profession and an athlete at heart. He entered the business of personalizing jerseys, as he says, out of necessity. A few bad experiences with suppliers of personalized jerseys were the last straw that made him decide to enter into a unknown business venture.

“I ran a sports club and on several occasions I was not satisfied, either with the delivered quality, or if the delivery deadlines were not met.

After one ugly episode, I didn’t sleep for several nights researching jersey printing and sewing technologies. The decision was made and within a few months the production was started. The first jerseys were made on a small Epson SC-F printer with a width of 110cm and a Chinese calender. We quickly outgrew this technology and installed an Epson SC-F9400 sublimation printer half a year ago.

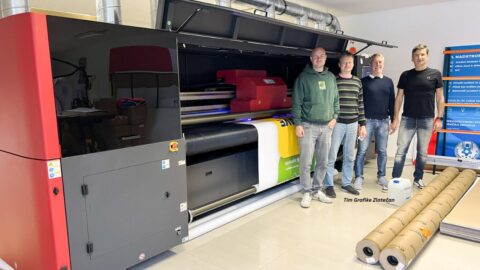

However, since it often happens that the printer works day and night, we decided that it needed help and invested in another identical printer. It was recently installed by service technicians from DIT company. So today, a few years later, we have a graphic department with five graphic artists who work on design and printing, a dozen women in finishing, on sewing machines and five people in administration and sales,” says Mr. Suvajac.

What are your experiences with Epson printers?

We started with another brand of sublimation printers, but there were problems with color management. Getting the color right on the fabric was very challenging. With Epson, the story is different. What we see on the screen always turns out exactly the same on the fabric. With jerseys, there is often repetition of jobs, some players leave the club, new ones arrive and we get requests to supplement the series. The print after six months or a year is identical to the first delivery of jerseys.

I would especially single out the black color, which is very strong with Epson. Other colors also burst with intensity, unlike many jerseys we see where black and other colors seem very poor.

Epson’s Edge Print software is very easy to use. We draw the design of the jersey in Corel, export it to pdf and then adjust the details of the preparation for printing in the Epson Edge Print software. Operators are satisfied with the simplicity and capabilities of the software, and the customer with the product.

Mechanical printers are very robustly made, from the paper roll transport itself to the massive printhead support. They are very quiet and fast in operation. We have installed double CMYK, eight tanks and once we start the printers, we forget that they are working.