Company JAK Ltd. from Ljubljana was founded in 1991, but entered the world of the graphic industry only in 2009, when started working in graphic design. In December 2013, they launched Printboutiq.com, an online application that allowed customers to design and order personalized phone cases online.

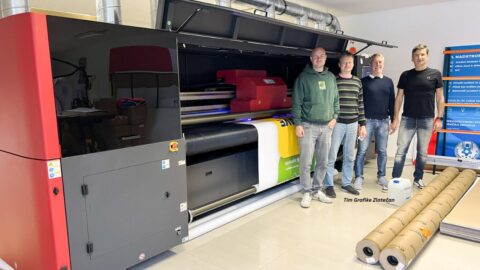

“Since we did not know how such products would be accepted on the market, we had an external contractor for the UV printing of the cases. Two years later, in 2015, on the recommendation of a business partner, from the company N.C.R. we bought our first Mutoh ValueJet 462 UF UV printer, which turned out to be an excellent decision. We have used it for more than eight years and recently replaced it with a newer and larger Mutoh XpertJet 661 UF model,” says Mr. Matjaz Kunc, owner and director.

As you said, you replaced the old Mutoh UV LED printer with a newer model. What was the deciding factor in choosing Mutoh once again?

I always tell everyone who wants to work with UV printers that UV printers must be loved! These are printers that need a lot of “care”, but if you take care of them, they return that love to you. The specificity of these printers are UV inks that require regular cleaning and maintenance. There are many DTO UV printers on the market, and considering that the Mutoh ValueJet 426 UF has served us well for the last eight years, the logical choice was the newer Mutoh XpertJet 661 UF. However, I cannot stress enough how important it is to have excellent technical support in all of this, and that of N.C.R. works at the highest level.

What are the most important improvements brought by the new model?

The benefits are different for each user. For us, the biggest advantages are certainly the larger print format, 483x594mm, the printer’s electric lifting table and the use of Gloss varnish. The printing of Gloss varnish is excellent due to the segmented UV light, and very rarely we encounter any defects in the varnish due to static electricity.

With the new printer and Mutoh Vertelit RIP software, we certainly accelerated production and increased the scope of use of Gloss UV varnish. One of the big advantages is that we can offer customers printing on A2 format objects up to 150mm high.

For what applications do you use it? What benefits do white ink and varnish bring you?

The UV DTO printer can be used to print on many different materials. We regularly use it to print personalized products such as phone cases, pictures on wood, personalized crayons for the youngest and graphite pencils. So, for the products that are offered on Printboutiq.com. However, we also regularly print on ID cards, plexiglass, forex. Also, printing on leather and artificial leather works very well, along with flexible colors.

Considering everything written, it is clear that we constantly use white color because in most cases the products we print on are not white. We regularly use varnish to protect the printing of our products, as well as to create special glossy effects that we can achieve with varnish.

How long have you been cooperating with the company N.C.R. and how would you describe the collaboration?

As I said before, cooperation with the company N.C.R. we started in 2015. It will probably be clear to everyone who reads this interview that we are very satisfied with them, otherwise they probably wouldn’t have bought a new UV printer from them! A bit of a joke, but really, they are always at our disposal. Anyone who has ever owned or used a UV printer knows how important support is in terms of advice and troubleshooting. It’s a production printer, but our production has never stopped for more than a few hours. N.C.R.’s service is extremely fast, and the service technicians are precise and always in a good mood. Sometimes I’m sorry that we don’t need their help more often!