Printing house Offset Tisak NP GTO has been ranked among the 150 best small and medium-sized companies in Croatia for many years. Founded in 1994 and co-owned by Mr. Predrag Vrza and Mr. Nenad Glavas. Today, it employs 55 permanent employees.

In their production program, they offer clients various graphic products. These are, for example, stickers, posters, folders, boxes, bags, banners, schedules, calendars, books, magazines …

The partner with whom the GRAFIK.net company has been cooperating for 15 years can unreservedly boast of an enviable production park. It includes, among other things, Kodak CtP, digital printers for sheet and roll printing, a four-color Heidelberg Speedmaster in B3 format and various finishing machines.

DIPS for uniform and optimal ink application

In order to speed up the machine preparation process, raise the quality to an even higher level, increase productivity and reduce waste when preparing the press, they decided to connect graphic pre-press and the new Heidelberg printing machine with the DIPS system.

Preparing the machine for print is one of the most important aspects for increasing productivity and reducing waste. In particular, this applies to the preparation of coloring, the uniformity of the application of ink and the achievement of optimal application of ink according to the standards for offset printing. The ink on the substrate is what the human eye sees and observes. Therefore its application is crucial for the quality of the product.

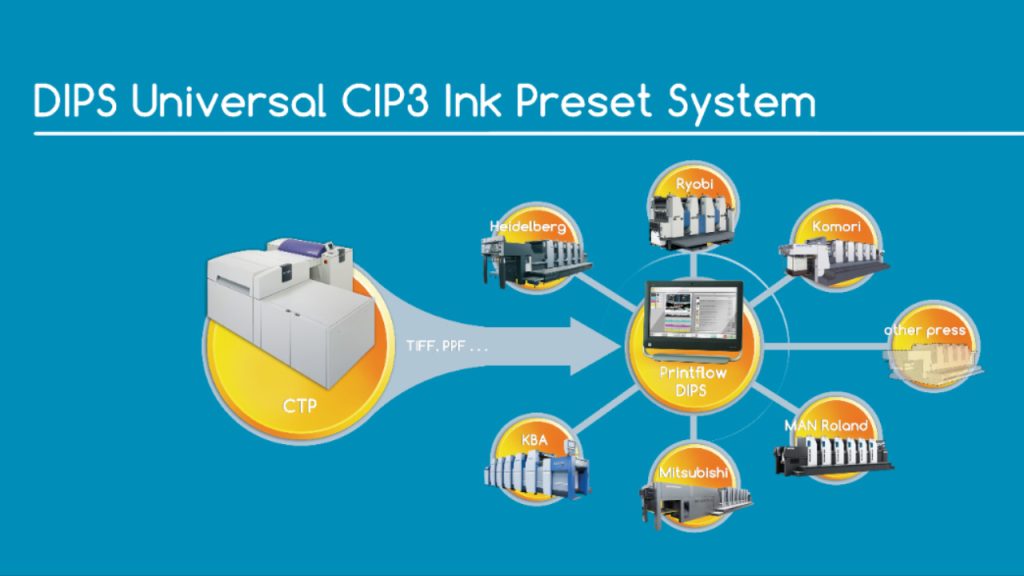

Digital Ink Preset System, abbreviated DIPS, is a solution of the Printflow company. It is a system that enables automatically programming ink key settings for each new job. All this in order to obtain uniform coloring over the entire surface of the printing sheet in the shortest possible period. As a result of quick and precise prepress, savings are achieved in time, but also in the material needed for the preparation of the machine.

Acting as a communicator between prepress workstations and the printing press, DIPS recalculates ink coverage information from the file sent for illumination to the CtP device. It then converts them into information about the required amount of ink per zone and the total amount of ink required and forwards them to the console of the printing machine.

Even the latest machines with the latest generation of print consoles can be connected to this system. This was exactly the case at the Offset tisak NP GTO. There, GRAFIK.net installed the DIPS system and connected Heidelberg with the latest generation Press Center 3 console and Kodak Prinergy workflow in graphic prepress.