The potential of digital textile printing is unquestionable. Speed, quality, ecology, on-demand production, personalization are just some of the advantages. From the very beginning, the company Grafko Caspar from Varazdin, Croatia, has recognized the digital textile printing potential with its investments. Among other brands, they use Kornit textile printing technology. One of their latest investments was the Kornit Presto digital roll-to-roll textile printer.

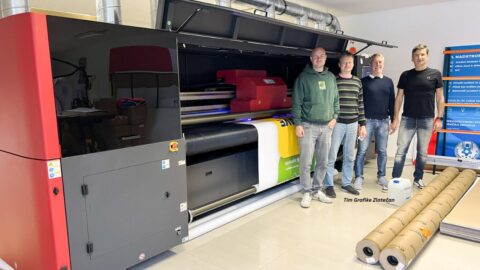

We spoke to Mr. Damir Hizak, owner of Grafko Caspar, in an interview for our Print Report YouTube series. In the recent years, they worked intensively and eventually managed to start the first Croatian Microfactory. Because of that, it was necessary to equip themselves with state-of-the-art technology. Kornit Presto, supplied and installed by Graphic Center, fit perfectly into this vision.

Kornit Presto is an industrial solution that prints directly on fabric in one step. It is an innovative solution for dry printing without the need to use water. This machine is using top-quality ecological pigment-based inks for printing – NeoPigment™ Robusto, thanks to which exceptional color fastness and resistance to washing are ensured. These are colors that have been developed in accordance with the goals of sustainability and are ECO PASSPORT and GOTS V5 certified. Therefore, their application is possible on natural materials such as cotton, silk or linen.

To realize the story of Caspar Microfactory, apart from the Kornit Presto roll-to-roll machine, another technology they invested in was DTG for printing on ready-made garments such as T-shirts, sweatshirts, hoodies… They didn’t want to leave anything to the case, so they got a DTG printer – Kornit Storm HD6.